Back in the day, Atari controllers seemed darned near indestructible. Now, 40 years later, they sometimes have issues, due to being around so long. The Atari paddle controllers have one main part where the difficulty shows up: The potentiometer - the part that turns your twisting into signals the Atari understands. Many times, they are just dirty from being 40 years old, and you can clean them without too much trouble.

How can you fix a jittery Atari 2600 paddle controller? Atari paddle controllers are pretty simple inside, but the potentiometer (the bit that translates twisting into control signals) can get dirty, or wear out. They are not hard to fix, and often just require opening them to clean out the junk.

Table of Contents

At the center of this issue, is the fact that you're having a problem with the potentiometer inside the controller (the electronic part that twists and sends signals to the Atari). There are 3 levels of fixing that you can do, depending on how serious your problem is. I recommend you work through these, starting with the simplest, and see what you actually need to do to get it working.

PRO TIP: If you are playing Activision’s Kaboom, you will see jitter at times. It’s not the paddles, but a known bug in the game. There - I just saved some of you a lot of frustration.

Don’t worry - this may sound too geeky for you, but it’s very straightforward, and I explain it carefully. All you need is some patience, and the right tools/supplies.

If you can not get your paddles working, or don’t want to bother, please don’t throw them away. Sell them as non-working, so someone else can get them sorted out. They have not been made in a long time, so we need to take care of what we’ve got.

Opening the Atari CX30 Paddle Controller

For all of the 3 levels of repair, you will need to open the Paddle controller, and get access to the potentiometer.

What You Will Need to Open the Atari 2600 Paddle Controller

- Medium-sized Phillips head screwdriver

- Tool to remove the nut holding the potentiometer

- 1/2" or 9/16" Socket (depending on nut type)

- or adjustable crescent wrench

- Newspaper or similar work surface that can get wet & dirty

Let’s start by getting the front knob off first, since it’s much easier to get off before you open the controller housing. The knob is just held on by tight fit, so all you have to do is grasp the controller in one hand, and the knob in the other, and pull the knob straight out from the controller body.

It’s important to note that the hole in the knob is designed to have a small metal clip inside it to make the knob fit on more snugly. You’ll see a thin, D-shaped fitting inside the D-shaped hole. On one of mine, the clip came out of the hole, and stayed attached to the white plastic shaft of the potentiometer. Just make sure you don’t lose it, or your knob may not stay on properly when you replace it.

Next, take a look at the nut at the base of the plastic shaft you just removed the knob from. If it’s the solid kind, you will need the 1/2" socket. If it’s the “hollow” kind, you will need the slightly larger 9/16". Or you can just use an adjustable crescent wrench to slot onto the nut. Remove the nut, and the washer below it, and set them aside.

Now flip the controller over, and use the Phillips head screwdriver to remove the two screws. Hold the front and back portions of the controller housing together firmly with one hand, while unscrewing with the other. This is because the trigger switch is not screwed down, but just placed inside (held in the proper spot by being situated on a registration peg), and it’s under a small amount of spring-loaded tension. When you open the housing, it’s easy for the button assembly to pop out of place, and for it to not be clear how it goes back in. No worries, since the reassembly instructions and photos will make it clear.

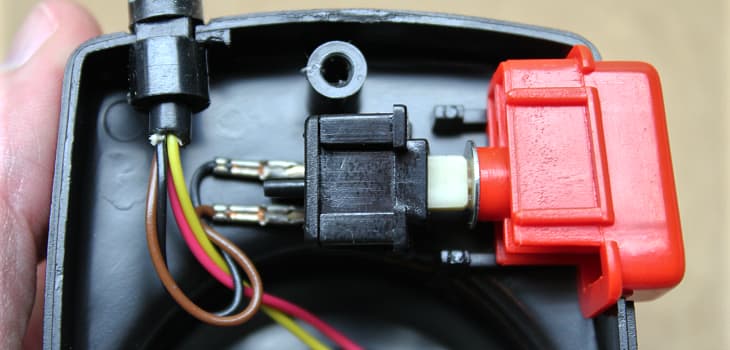

Once the screws are removed and set aside, hold the controller with the back facing directly up, and gently remove the back portion of the housing. Apply very slight pressure to the button, just enough to hold it in place as you take the back cover off. Note two key things about the button assembly before you do anything else, because when you reassemble later, it may not be obvious how it goes back in:

-

Note 1: The orange button itself has a lip extending out from the button at the top and bottom. This keeps it from sliding out further than it should when the button is released, and the spring pushes it back out. That lip should rest just inside the housing, as seen in the photo below.

-

Note 2: Note how the black switch mechanism that the big orange button operates, is situated. The two wire connectors are up against the inside of the front (farthest from you - against the “floor” of the housing as you are looking into it from the back). It is seated on a registration peg - molded into the controller housing. The peg should slot in right between the two wire connectors.

Gently pull the orange button toward you, so it slips out of the housing. Remove it from the end of the white plastic shaft coming out of the black switch mechanism. Don’t lose the small, thin washer on the white shaft.

Finally, take hold of the molded cable bushing where the cable passes into the housing, and gently remove the housing and set it aside.

Lay the cable and two attached components on a work surface you can get wet and dirty. I am using newspaper.

Now you are ready to work on that potentiometer.

Paddle Repair Level 1: Clean the Closed Potentiometer

A potentiometer is just a dial that makes an electrical connection inside, which changes as you turn it. The key is that metal contacts are making that connection, and over time, air, dirt, moisture... all can affect those metal contacts, and make them conduct electricity less effectively, or not at all. That’s what causes the glitchiness and causes your onscreen jitter.

What You Will Need to Clean the Closed Potentiometer

-

Spray can of electronic contact cleaner. My local auto parts store carries this, too. Just make sure what you buy leaves no residue, and is safe for plastics.

-

Rubber glove, or plastic bag to cover your hand

Potentiometers are semi-closed components. You can get cleaner inside through the window opening where the 3 terminals (wire connections) come out. To do this, hold the pot on its side by the shaft, with the window facing toward you. Use a glove or put that hand in a plastic bag so you don’t get the cleaner on your hand.

Attach the application tube to the nozzle on your electronic contact cleaner, and place the end of the nozzle at the window on the pot. Give a short burst of spray (1/2 second), and set the cleaner aside. Now hold the pot housing, and twist the shaft all the way one way, and then all the way the other way a few times. Spray again, and twist again. Read and follow the can’s safety precautions. Wash your hands when done. Don’t try to use WD-40 for this, since it’s not intended for controls, and leaves a residue that can cause real problems with the contacts. You can however, level up what you’re using, and go with something like DeoxIT, a more premium product that lubricates along with cleaning.

Give it a little time to dry, and then plug the controller cable into your Atari and test it. You don’t need to reassemble the whole thing, just hold the pot in one hand (being sure not to touch the terminals so you don’t confuse the Atari), and twist the shaft to try it out. If it works smoothly, you’re done. If it’s improved, but not all the way, try spraying again.

If you get it working properly, wipe off the potentiometer, and proceed to the end section on Reassembling the Atari Paddle Controller.

If it still does not work properly after multiple tries, proceed to Level 2 below.

Paddle Repair Level 2: Open and Clean the Potentiometer

If you have performed the Level 1 steps and you still have jitter, you’ll want to open up the potentiometer to clean it. This is easy to do, and just requires a little care.

You will be bending the tabs on the potentiometer housing to get it open. You can probably bend them back and forth a couple of times before the tabs get metal fatigue and break off. Work gently, and bend them only as much as you need to.

What You Will Need to Open and Clean the Potentiometer

- Small flathead screwdriver with a thin blade

- Needle nose pliers

- 91% isopropyl alcohol

- Cotton swabs

Opening the Potentiometer

The potentiometer will have either 4 or 6 tabs holding it shut, depending on which variation was used at the time of manufacture. Place the potentiometer on a flat work surface, grasping it firmly between your fingers. Take a small flathead screwdriver with a thin blade, and carefully work it underneath one of the tabs. Coordinate pressing with a thumb against the direction you are pressing with the screwdriver, and be mindful not to jab yourself with it if it slips.

Once you get each of the tabs up a little bit, bring in your needle nose pliers and very gently bend the tabs back only as far as you need to in order to get the brown wafer board out. Don’t over-bend, to avoid fatiguing the metal and making the tabs more prone to breaking.

When the tabs are out of the way enough, lift the threaded collar up and off the shaft. Note where the little raised pip is on one side, and place it on your work surface. Keep it oriented in the same way it was on the pot, so you can put it back on the same way when you are done.

Interesting note: While talking to a tech at Mouser Electronics, I learned that this collar is called the bushing. Now you can sound like an insider.

Next, lift the brown wafer board up and off of the shaft, flipping it over to get a look at it. You will likely see some dark gray gunk on the dark gray track on the wafer board, as well as on the raised contacts on the brass sweep.

Cleaning the Potentiometer

Start with cleaning the brass sweep. Wet a cotton swab with 91% isopropyl alcohol, and very carefully wipe the gray gunk off of the side with the two flat blades facing each other. Note how the cotton head wants to catch on the sharp and pointy parts of the contacts, and avoid catching it, since you can accidentally bend one. Short strokes work best.

Once you have the feel for this, do the other side with the two sets of three tiny fork tines. Be extra careful on these, since those tines are so small, and it’s very easy to snag the swab on them. When you are done on both sides, make sure that no stray cotton fibers are left on the sweep.

Now clean the circular track on the brown wafer board with a fresh swab and alcohol.

Reassembling and Closing the Potentiometer

Place the plastic and brass sweep/shaft back into the metal housing.

Next, flip the wafter board over, and lower it down on the shaft into place.

Then place the bushing (the threaded metal collar) on the shaft and lower it so that the little raised pip on the one side is in the same place it was when you took it off.

Finally, use your pliers to bend the tabs back down flat, securing everything in place.

Now jump down to the steps on Reassembling the Atari Paddle Controller.

Paddle Repair Level 3: Replace the Potentiometer

Potentiometers are not complicated devices, so the Level 2 cleaning should do everything you need. There are times though, that you may have to completely swap out the potentiometer for a new one. There are a few options for this, and I will offer some commentary on each, and a how-to for the process.

The potentiometer in your paddle was made specially for Atari. It’s not a common off-the-shelf part you can just pick up, unfortunately.

After a LOT of digging around through Google, forums, and blog pages, the options distill down to these 3:

-

Buy the Super Pot from Best Electronics in California. They are Atari specialists, and have spent decades working to find the perfect replacement as far as size and function - eventually getting them specially made. They are a little pricey, at $12 a piece (min purchase: 2), but they are manufactured to have 10 times the lifespan of the original. Note that you will need to call them to order, since they don’t have an online store.

-

Use donor pots from other controllers. They can sometimes be found on eBay. Alternatively, you can salvage them out of other paddles that have issues, but still have good pots.

-

Modify an existing 3rd party pot. This Radio Shack potentiometer (Yes! Radio Shack is back as of 2019!) has been used by some folks to replace their dead Atari one. Modifications are needed, though. The shaft is too long and needs to be cut. the shaft is also round, and needs to be either cut to match the original’s D-shape, or the hole in the paddle knob must be routed out (yikes!) to fit the round shaft. Downside: getting that to match exactly is a roll of the dice. Also, you need to grind off part of the inside of the paddle housing to accommodate the slightly different shape of this pot. Personally, that was all a bit too much for me.

If you’re good enough to have a go at option 3, I’m sure you can sort out the particulars yourself.

For options 1 and 2, you just need to desolder the old one, and solder the new one in. This really is about the easiest soldering you can do, so don’t sweat it.

What You Will Need to Replace the Potentiometer

- Soldering iron

- Solder

Carefully note which colored wires go to which terminals (purple to center, yellow to right, when the pot is flat and terminals are facing you).

Use the soldering iron to heat up and remove solder from the spot where the wire connects to the terminal. You can do this with just the iron, if you are patient and gently pull on the wires to remove them from the terminals when the solder liquifies.

Now bring in the new potentiometer, and solder the wires to the same terminals they were attached to on the last one.

Once completed, let it cool for a moment, and then proceed to the Reassembling the Atari Paddle Controller section

Reassembling the Atari Paddle Controller

Once you have completed whatever cleaning or repair was needed, it’s time to put the controller back together.

Begin by placing the potentiometer into the front part of the controller housing so that the shaft goes through the hole, and the 3 terminals coming off the one side of it point toward the narrow end of the controller (so they are between the two plastic pegs). Press the pot in so that it snugs into the hole, and hold it in place with the terminals centered between the pegs. Still holding the pot in place, flip the controller over, and replace the thin washer (if there is one) and then screw down the nut onto the threaded bushing. Use your socket or crescent wrench to tighten it until it’s snug.

Important point: With all tightening involving plastic parts, especially the screws the hold the housing together - be gentle and tighten only until it’s snug. The plastic is old and brittle, and can break if stressed too much.

Now find the widest notch on the molded plastic bushing (the “strain relief”) on the cable (the one closest to the exposed wires). Turn the cable until you find the flat side in this notch. Slot the notch into the notch on the wide end of the controller housing, so that the flat portion faces out. Make sure it’s snugly in place.

Now make sure the thin washer is on the button switch’s white shaft. Turn the switch until the shaft points in the direction of the button opening, and the two wire terminals are on the side closest to the interior of the housing. Place the orange button onto the end of the white switch shaft, with the notched part of the button’s rectangular shape toward the narrow part of the controller.

Push the button in slightly, so that the lip on the top and bottom is inside the edge of the housing. Now situate the black switch so that the two wire leads coming off its back straddle the plastic registration peg molded into the controller housing. The spring action of the switch should hold the whole button assembly in place.

Now replace the back of the controller housing, making sure the edges all line up, and nothing is sticking out, or poorly positioned. Hold the housing closed with one hand, and work the button with the other to make sure it operates freely. If it binds, take the back off, and adjust things to get it properly seated.

Once the housing is closed and everything is working properly, gently screw the two Phillips head screws back in, taking care not to over-tighten. Finally, flip the controller over, match the D-shape on the potentiometer post with the hole in the knob, and push the knob down onto the shaft.

You’re done!